Product

COB LED is a compact, high-brightness light source that integrates multiple LED chips into one package, with the characteristics of high reliability and good heat dissipation. In simple terms, its production method is as follows:

Substrate preparation: The first step is to select a suitable substrate as the bottom support of the COB light source. Metal materials such as aluminum or copper substrates are usually used, and thermal conductive glue or thermal conductive adhesive is applied to the substrate for fixing and heat dissipation.

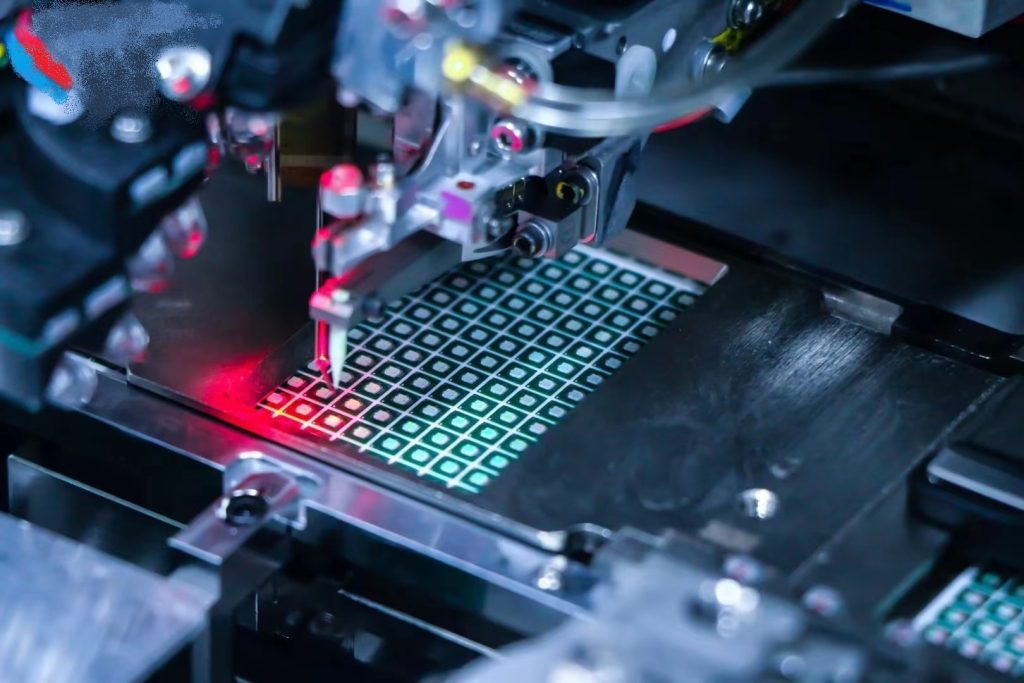

Paste LED chips: Paste multiple LED chips to the substrate according to the design requirements. Usually, automated equipment is used to accurately position and paste the LED chips. Avoid gaps or bubbles that cause poor heat dissipation.

Circuit connection: Use materials such as gold wire/copper wire or conductive glue to connect the LED chip to the lead or circuit on the substrate. This requires high-precision welding equipment and technology to ensure that the welding is firm and the effect is consistent.

Heat treatment: Fill the gap between the LED chip and the substrate with thermal conductive materials such as thermal conductive glue and thermal conductive adhesive to improve the heat dissipation efficiency. Provide good electrical connection and heat conduction.

Encapsulation curing: Place the COB light source in a specific curing device, and use UV irradiation or thermal curing to cure the thermal conductive glue or adhesive to ensure a stable connection between the LED chip and the substrate. Encapsulation can enhance mechanical strength and durability, and can also adjust the direction of light to improve its utilization rate.

Lighting test: Perform lighting test on COB light source, including performance test on brightness, color temperature, color uniformity, etc., and ensure the quality of COB meets the requirements through equipment with optical testing capability, and rework or eliminate unqualified products.

Classification and packaging: After the lighting test, COB light source is classified and packaged, usually with packaging glue, plastic box or tape for protection. By completing these steps, high-performance and high-reliability products can be obtained. With the continuous development of COB LED technology, COB LED will be more widely used in various industries.

下一篇: