Product

What is Chip-on-board (COB) LED lighting technology? Unlike its predecessors, this technology entails combining several LED chips and attaching 9 or more diodes under one module. The chips are tightly integrated onto a single silicon-carbide circuit board.

Upon attaching the COB chips to the base, manufacturers coat the light strip with phosphor to enhance a seamless illumination effect.As LED technology evolves and gains traction in the lighting industry, the demand for this modernized lighting tech is increasing rapidly. The rise in demand rates has attracted many investors into the COB LED market, thus shifting the supply curve.

Visionary manufacturers have dedicated their resources to introducing cutting-edge technologies to deliver a versatile taste to their consumers. That is, enhancing their adaptability, usability, and energy efficiency levels. The COB and SMD LED are currently dominating the LED illumination industry.

Time to discuss COB LED lighting, its typical applications, and exclusive features that make it stand out amongst other lighting options.

Although the COB technology is still new in the illumination industry, its features and applications have captivated manufacturers and consumers. Unlike incandescent lights, LEDs generate light by combining numerous LED chips to create one module.

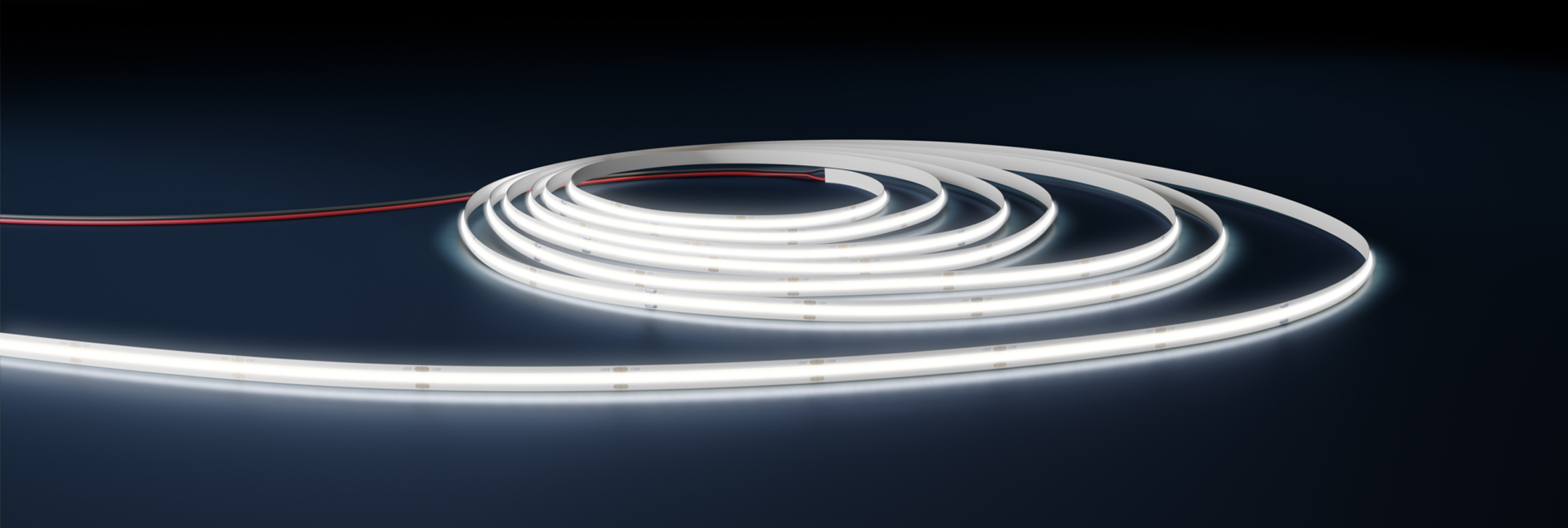

Manufacturers attach the chips to a single silicon-carbide circuit base. Packing these chips closely together creates one homogeneous lighting strip, the primary light source in the COB LED lighting system.

The chip arrangement leaves no room for light hotspots when illuminating surfaces. That’s why COB LED lights are a renowned lighting application, especially in the film and photography sectors.

Regardless of the number of diodes on the light chip, all COB LEDs contain one circuit and two contacts. The primary circuit arrangement of the COB creates a panel-like illumination design that is utterly eye-catching. Bigger COB chips can produce a marvelous light intensity of around 250 lumens (25 mA).

Here’s a list of exclusive features of LED chips:

· They come in different shapes.

· They are small and weigh lighter than conventional LED chips.

· Depending on their design, COB LED chips can create varying degrees of light. These chips can be built to emit intense, colorful light beams and light at different temperatures.

· On average, each COB LED chip contains nine, ten, or more diodes.

· Each COB LED chip has one circuit.

· There are only two contacts that power each COB LED chip.

· They last longer than conventional lighting technologies (25 times longer)

Typically, LEDs are built to generate reliable and durable light in residential, commercial, and industrial environments. COB lights play two significant roles in the illumination industry — illumination and indication purposes. The COB LED technology has exceptional illumination features, which make it an ideal lighting option for consumers across various applications.

Apart from providing a great deal of light intensity, COB lights are also acknowledged for their seamless light distribution. Here’s the deal breaker: their lighting lifespan! Compared to traditional lighting sources, COB LEDs last for ages (40,000 – 70,000 Hours).

The Chip-On-Board tech is widely used in illuminating residential settings (both indoor and outdoor), commercial spaces, and architectural structures. Additionally, COB LEDs have taken the film production and photography industries by storm.

COB lights come in handy in situations that demand exceptionally homogeneous, intense light beams. However, they perform better in confined areas than in large and open ones.

What makes COB lighting stand out? COB lights allow you to control and adjust the warmth or coolness of your room’s lighting (color temperature).

Moreover, COB LEDs have other impressive features and modes that win people’s hearts. The ability to adjust color temperatures while maintaining its color rendering is remarkable. These features make the lighting technology perfect for decoration, stage lighting, events, photography, film production, you name them.

The high lighting intensity of COB lights is also beneficial when used to catch the eye of a distant audience. Businesses have widely used this application to run advertisements tailored to attract customers using billboards and digital posters. COB LEDs provide brighter displays suitable for drawing attention to a confined setting.

COB lights have a broad range of applications, which make it a flexible and outstanding lighting option. They serve endless lighting solutions in the illumination industry, thus the uprising demand levels from tons of customers.

1. Blue LED chips are the primary light source for white COB LEDs.

2. White COB LEDs have a phosphor coating/layer that absorbs lighting energy from the light source. This converts the light emitted, e.g., blue, to white.

3. COB Led chips are mounted to a thermal-conductive ceramic or aluminum substrate base.

4. The chips and phosphor coating are covered by an encapsulation material, which protects the components from damage.

5. COB LEDs have a heatsink around the substrate to maintain heat generated during lighting. The heatsink regulates the heat by drawing it away from light chips, thus enhancing its lifespan and overall efficiency.

Manufacturers place COB LED chips close together on a single substrate, thus saving more space over typical LED chips. This arrangement is beneficial to you in many ways.

You get high-density light because the chips are tightly packed to produce large concentrations. Furthermore, you don’t have to worry about the space occupied because they fit small spaces. The close placement of the chips enables COB LED lights to come in compact forms and sizes, such as strips that you can carry around easily.

1. COB LEDs generate a great deal of light intensity. They supply high-concentration light due to the compact chip arrangement.

2. Depending on the design, COB LEDs have various applications. They have potential applications, including agriculture, interior, and film lighting.

3. COB lights save a lot of space. COB LED chips are close together, allowing them to fit in small light outlets like strips.

4. Tunable white COB LEDs allow temperature adjustment to provide the desired light grade for particular settings.

5. There is a wide range of colors available to choose from when purchasing COB LEDs.

6. They Have low energy consumption, which will, as a result, reduce the cost of your electric bill.

1. They are more expensive than regular LEDs. Although they have a low energy consumption rate, their price tag is relatively high.

2. They have a limited color range when compared to traditional LEDs such as RGB LEDs.

3. Repairing COB LEDs can be a challenging process. This lighting technology is still new in the industry, and only some technicians understand it.

4. Exposure to COB LED lights for a long time might harm your eyes and skin. Beware.

5. They are less efficient at lighting large spaces than small ones.

6. COB LEDs are more expensive due to their high upfront costs. The costly price tag arises from the materials and advanced technology used to manufacture this lighting system.

1. Sterilization: You can design COB lights to produce ultraviolet light to disinfect against different destructive microorganisms. COB LED lighting can purify water, air, and object surfaces.

2. Advertisements: Businesses utilize high-intensity COB lights to calibrate eye-catching brand names that attract customers to their premises.

3. Source of light for farming: Farmers use COB lights to supply concentrated light to plants in the agricultural sector. This application is useful in areas that receive little or no sunlight. COB chips have impacted horticulture since the illumination enhances photosynthesis, thus helping the struggling plants grow.

4. Film production: COB LEDs have transformed the film production industry. This lighting technology provides several features that have proven significant for the film and theatre setting.

5. Decoration: There are several COB LED variants that are specifically manufactured for decoration purposes. COB light strips complement both outdoor and indoor spaces since they allow you to freely adjust the illumination of your space on a flexible scale.

The COB LED lighting technology has gained global popularity given its diverse applications that serve numerous lighting solutions to consumers.

From providing compelling aesthetics in residential and commercial spaces to transforming the digital film production industry, you won’t regret reviewing NSELEDCLOUD’s extensive guide regarding how COB LED and traditional LED applications differ.

1. COB LEDs have multiple chips installed closely, while regular LEDs use a single chip.

2. COB LEDs use a smaller space compared to regular LEDs.

3. Tunable white COB LEDs enhance flexibility, allowing you to raise or reduce light temperature.

4. COB LEDs are relatively more expensive than regular LEDs.

5. COB LEDs consume less energy than standard LEDs