Product

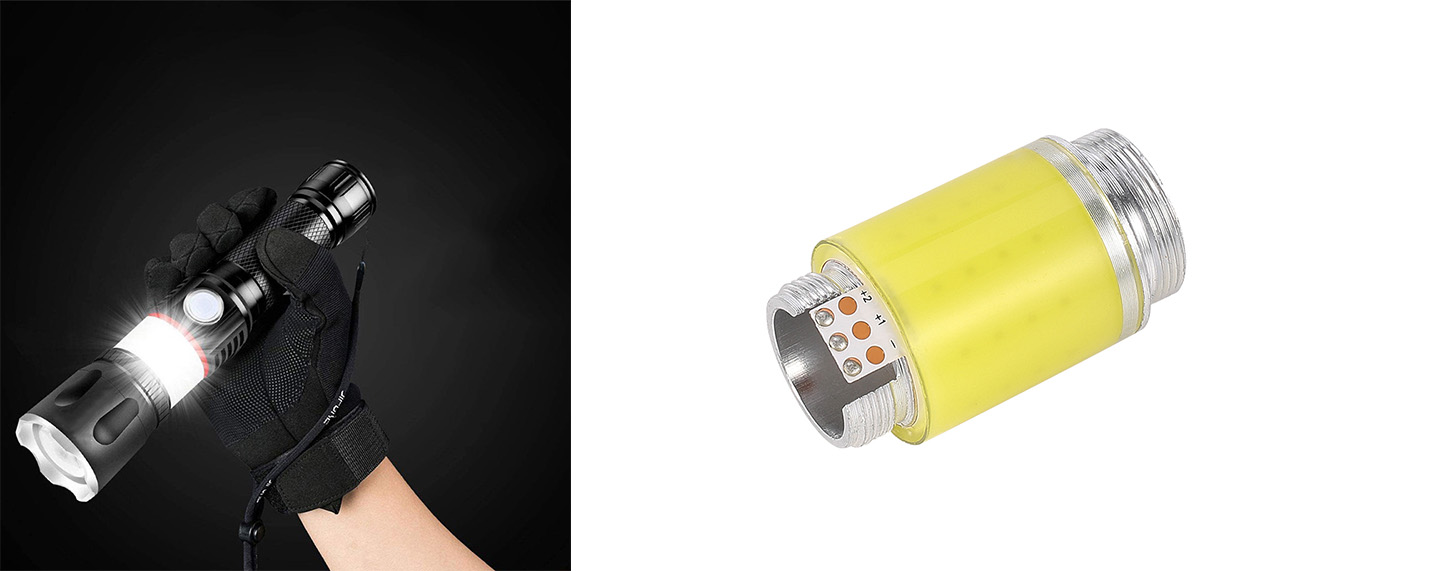

Chip-on-board (COB) LEDs are a relatively new addition to the LED market and offer several advantages over standard products. A COB LED is a single module formed by the manufacturer bonding multiple LED chips (usually nine or more) directly to a substrate. Because the individual LEDs used in COB are chips rather than traditional packages, these chips take up less space after mounting and can maximize the potential of the LED chips. When using multiple SMD LEDs mounted closely together, the powered COB LED package behaves more like a lighting panel rather than multiple independent light emitters.

Today, with the rapid development of LED technology, chip-on-board (COB) LED has become a hot topic in the industry. Imagine that multiple tiny LED chips are tightly arranged like a puzzle and directly bonded to the same substrate. This is the basic concept of COB LED. Due to this unique packaging method, COB LED shows significant advantages in lighting effects, space utilization and thermal management. Let’s talk about the biggest highlight of COB LED – its light efficiency and uniformity. By densely arranging many small chips on the same plane, COB LED can emit more uniform and continuous light, avoiding the spot or shadow problems that may occur in traditional LED lamps. This makes it particularly suitable for applications that require uniform lighting, such as commercial display lighting or stage lighting design. Then there are its energy-saving and efficient features. Traditional multi-chip LED solutions require separate wiring for each chip, while COB LED requires only two contacts to power all internal chips, greatly simplifying circuit design and reducing manufacturing costs. At the same time, because the number of components is reduced, the amount of heat generated is also reduced accordingly, making COB LEDs have better heat dissipation performance, thus extending the service life. The compact design of COB LED makes it excellent in saving space. The compact size not only reduces the overall weight, but also makes installation more flexible, especially suitable for applications with extremely high space requirements, such as internal lighting of portable equipment or precision instruments. Of course, no technology is perfect. One potential problem with COB LEDs is that if one chip fails, it can affect the operation of the entire module. This requires us to pay more attention to quality control and reliability testing during design and use to ensure that each COB LED can operate stably. It is worth mentioning that COB LED is not just a light source, it is more like an innovative concept. It breaks the design and application boundaries of traditional LEDs and provides us with a new lighting experience. In the future, with the further development and optimization of technology, we have reason to believe that COB LED will shine in more fields and bring more convenience and beauty to our lives.

Advantages of COB LED

Thanks to their multi-chip packaging, the COB LED's light-emitting area can accommodate several times the light source of a standard LED, significantly increasing lumen output per square inch.

COB LEDs use a single circuit with only two contacts to power the multiple diode chips inside them. This results in fewer components per LED chip being required for normal operation. In addition, lower component count and the elimination of traditional LED chip structure packaging can reduce the heat generated by each LED chip. The COB LED's ceramic/aluminum base also acts as a more efficient heat transfer medium when an external heat sink is installed, further reducing the overall operating temperature of the component. When attaching the COB to a radiator, it is important to carefully select a radiator that can dissipate the heat generated so that the COB can reach its full potential. In the long run, good cooling improves energy efficiency and reduces failure rates.

Another reason COB LEDs can reduce failure rates is that individual LED chips no longer require spot welding because each chip is mounted directly to the substrate. Fewer solder joints means lower failure rates.

Since lenses and other traditional LED packaging components are no longer required when using COB LEDs, light loss is greatly reduced and viewing angles are increased.

Disadvantages of COB LEDs

COB LEDs do have the disadvantage that they are currently only available in a limited number of colors (blue, green, pink, red, cool white, natural white, and warm white).

COB LED lighting applications

COB LEDs have a wide range of applications. While COB LEDs can be used for higher output general lighting, these devices are primarily used as solid-state lighting (SSL) fixtures to replace metal halide lamps in applications such as high bay lights, street lights, and high-output track lights and downlights. .